SILICA and DeltaMem AG: Innovative Partnership

DEHYDRATION OF LIQUIDS

DEHYDRATION OF SOLVENTS BY ADSORPTION OR MEMBRANES

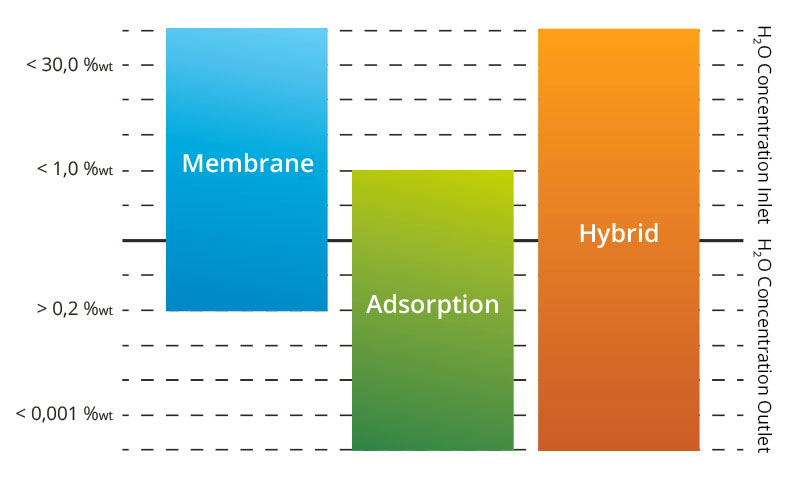

Organic solvents can be excellently dried with the aid of adsorbents or membranes. Depending on the application, SILICA offers a very wide range of drying processes. With SILICA adsorption plants, residual water concentrations in the solvent of only a few ppm can be achieved. For the removal of a high water content of up to 30 %, the use of pervaporation membranes is recommended. Based on the desired residual water concentration, we can offer either membrane plants or modular hybrid plants equipped with PERVAP ™ membranes from DeltaMem AG .

Lowest residual content in

the ppm range

ADSORPTION PLANTS FOR

DEHYDRATION OF SOLVENTS

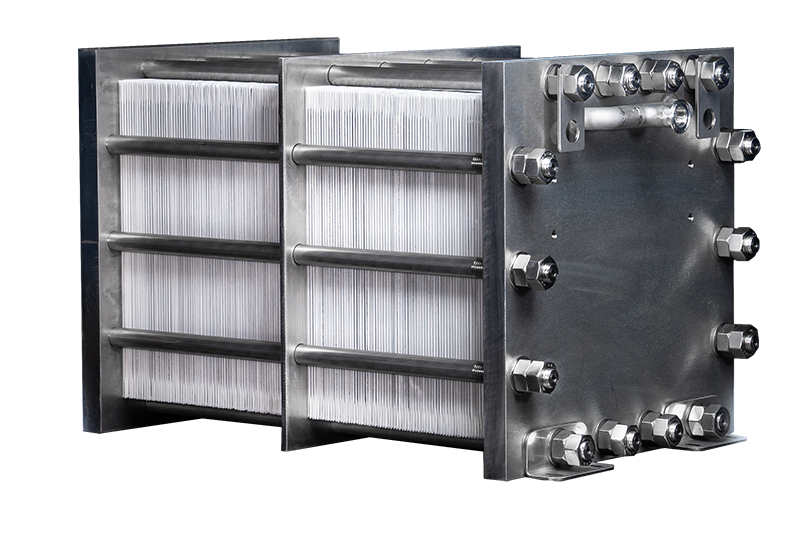

The drying of organic solvents is a demanding application of adsorption technology. The water contained in the solvent is adsorptively bound to special molecular sieves. In addition to the water, other interfering impurities can also be adsorbed. Usually, the adsorption plant operates continuously with two adsorbers being operated alternately: one is drying while the other one is getting regenerated.

During regeneration the previously adsorbed moisture is desorbed by heating the adsorber and condensed in a downstream heat exchanger. Adsorption is used for drying organic solvents with inlet water contents <1.5 %. Depending on the organic liquids to be dried, residual moisture contents down to 1 ppm wt can be achieved.

Hybrid drying systems: The best of both worlds

DEHYDRATION OF LIQUIDS

DEHYDRATION OF SOLVENTS BY ADSORPTION AND MEMBRANES

The hybrid drying plant combines the advantages of pervaporation and adsorption technology in one process. By smartly interconnecting both processes, organic solvents with inlet water contents < 30 % can be dried down to residual moisture contents of 1 ppm wt. The respective limitations of the individual processes are eliminated by the hybrid process. SILICA designs and builds the complete turnkey hybrid plant equipped with PERVAP™ membrane modules according to the customer’s individual requirements – Swiss quality membranes combined with plant engineering Made in Germany.

The hybrid drying process provides the following benefits to our customers:

Lower energy costs, up to 50 % less steam consumption compared with distillation

Compact design with small footprint, also suitable for indoor installation

Turnkey modular plant with few interfaces in the overall process

Continuous process even for low throughputs

Very high solvent recovery rate

Fully automated operation

Application of the SILDRY process

LIQUID DEHYDRATION TECHNOLOGY

FOR A VERY WIDE PROCESS RANGE

Application for drying of:

Alcohols

- Ethanol

- n-Propanol

- Isopropanol

- Butanol (all isomers)

- Pentanol (all isomers)

- Allyl alcohol

- Benzyl alcohol

- Cyclohexanol

Ester

- Methyl acetate (MeAc)

- Ethyl acetate (EtAc)

- Butyl acetate (BuAc)

Ether

- Methyl tert-butyl ether (MTBE)

- Ethyl tert-butyl ether (ETBE)

- Di-iso-propyl ether (DIPE)

- Tetrahydrofuran (THF)

- Dioxane

Ketones

- Acetone

- Butanone (MEK)

- Methyl isobutyl ketone (MIBK)

Nitrile

- Acetonitrile (ACN)

Your contact to SILICA

SILICA: INDIVIDUAL, COMPETENT, RELIABLE

We treat every request confidentially and conscientiously. We want you to be

completely satisfied with our work!

Your customised plant: We will be happy to advise you personally